Phone: +86 18966915318

E-mail: sales05@nutritionoem.com

Add: Room 815, Unit 1, Building 1, Zhongjian Caizhi Plaza, Mingguang Road, Yuanding Road, Economic And Technological Development Zone, Xi'an, Shaanxi, China

Guide to Selecting a B2B Dietary Supplement Manufacturer

Here is a comprehensive guide on how to select a B2B supplement manufacturer, written in English and exceeding 1500 words.

A Comprehensive Guide to Selecting a B2B Dietary Supplement Manufacturer

Introduction

In the rapidly growing and highly competitive dietary supplement market, the choice of your Business-to-Business (B2B) manufacturing partner is one of the most critical strategic decisions you will make. This partner is not merely a supplier; they are an extension of your brand, responsible for transforming your vision into a safe, effective, and high-quality product that consumers trust. A subpar manufacturer can lead to catastrophic consequences, including regulatory actions, product recalls, reputational damage, and ultimately, business failure.

Selecting the right partner requires a meticulous, multi-faceted due diligence process. This guide provides a detailed, step-by-step framework to help brands, from startups to established companies, navigate this complex selection process and identify a manufacturer that can serve as a cornerstone for long-term success.

Phase 1: Internal Discovery and Requirement Definition

Before contacting any potential partners, you must have absolute clarity about your own needs and goals.

1.1. Product Definition and Formulation:

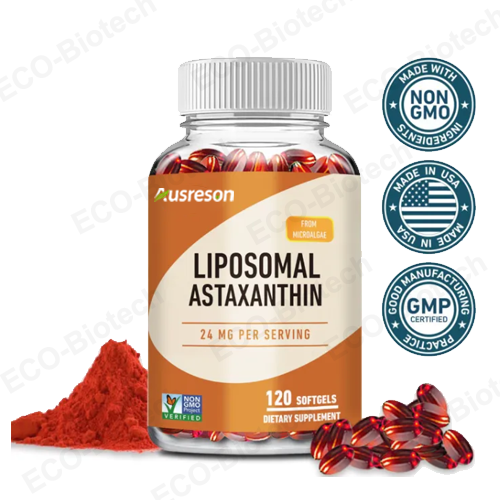

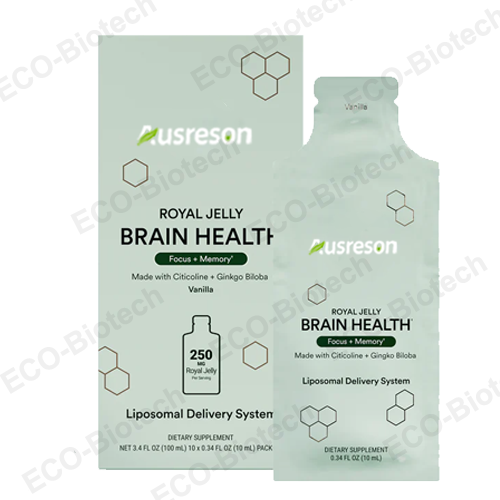

Type of Product: Precisely define what you are creating. Is it a softgel, hard-shell capsule, tablet, powder, liquid, or gummy? Each form has different manufacturing requirements and cost implications.

Formulation Complexity: Do you have a finished formula, or do you need the manufacturer's R&D team to develop one? Are you using standard ingredients or novel, patented compounds? Complex formulations may require specialized equipment and expertise.

Target Audience: Who is the product for? Specific demographics (e.g., seniors, athletes) may influence factors like capsule size, dosage, and excipients used.

1.2. Quality and Brand Positioning:

Quality Tier: Are you aiming for a mass-market, value-oriented product or a premium, clinically-backed supplement? Your positioning will dictate the level of quality control and ingredient sourcing you require.

Certifications: Determine which certifications are non-negotiable for your brand identity. Common ones include:

GMP (Current Good Manufacturing Practices): This is a baseline requirement, not an option.

NSF International: Indicates product and facility safety.

UL/Eurofins: Third-party testing and certification.

Organic (USDA): If using organic ingredients.

Non-GMO Project Verified: For non-GMO claims.

Vegan, Gluten-Free, Kosher, Halal: As required by your target market.

1.3. Volume and Scalability:

Initial Order Quantity: Be realistic about your first order. Many manufacturers have high Minimum Order Quantities (MOQs). Find a partner whose MOQs align with your budget and sales projections.

Growth Projections: Can the manufacturer scale with you? Inquire about their capacity to handle a sudden surge in demand, such as after a successful marketing campaign or a key retail placement.

1.4. Budget and Commercial Terms:

Total Cost Analysis: Look beyond the per-unit cost. Factor in tooling fees (for custom capsules or tablets), setup charges, packaging, and shipping. Understand their payment terms (e.g., deposit structure).

Phase 2: The Due Diligence Process - Evaluating Potential Partners

With your internal requirements defined, you can begin the rigorous process of evaluating manufacturers.

2.1. Regulatory Compliance and Quality Systems

This is the most critical area of evaluation. A failure here poses an existential risk to your business.

GMP Compliance: The facility must be cGMP compliant as per the U.S. Food and Drug Administration (FDA) under 21 CFR Part 111. For international markets, ensure compliance with relevant bodies (e.g., Health Canada, TGA Australia, EFSA in Europe).

Third-Party Audits: Always request a recent third-party audit report (e.g., from NSF, UL). This provides an unbiased assessment of their quality systems. Be wary of a manufacturer that is hesitant to share this.

Standard Operating Procedures (SOPs): Inquire about their SOPs for every stage of production, from raw material intake to finished product release.

Testing Protocols: A reputable manufacturer will have a robust testing program:

Incoming Raw Materials: Every ingredient batch should be tested for identity, purity, potency, and contaminants (e.g., heavy metals, pesticides, microbes).

In-Process Testing: Testing during manufacturing to ensure consistency.

Finished Product Testing: Every batch of finished product must be tested to verify it meets label claim for potency and is free from contaminants.

Stability Testing: They should conduct stability studies to establish and verify the product's shelf life.

2.2. Research and Development (R&D) and Technical Expertise

A strong R&D team is a sign of a sophisticated manufacturer.

R&D Capabilities: Do they have in-house scientists and food technologists? Can they help you refine your formula for stability, bioavailability, and cost-effectiveness?

Innovation: Ask about their experience with new delivery formats (e.g., delayed-release capsules, liposomal liquids) or novel ingredients.

Problem-Solving: Present a hypothetical challenge (e.g., a formulation with poor flow characteristics) and ask how they would address it. Their response will reveal their practical expertise.

2.3. Sourcing and Supply Chain Integrity

The quality of the final product is only as good as the quality of the ingredients.

Supplier Vetting: How do they qualify and audit their raw material suppliers?

Ingredient Traceability: Can they provide full traceability for their key ingredients back to the original source?

Inventory and Sourcing Power: Do they maintain large inventories of common ingredients to ensure supply continuity? Do they have the purchasing power to secure high-quality ingredients at good prices, which can benefit you?

2.4. Manufacturing Capabilities and Capacity

Facility Tour: Whenever possible, conduct an on-site audit. A virtual tour is a minimum requirement. Look for organization, cleanliness, and modern, well-maintained equipment.

Equipment and Technology: Do they have the specific machinery required for your product type? Are their systems automated to reduce human error?

Production Lines: How many production lines do they have? Are there dedicated lines for major allergens (e.g., soy, gluten, shellfish) to prevent cross-contamination?

Capacity Utilization: Ask about their current capacity. A facility running at 95% capacity may struggle with your new order, while one at 50% might raise questions about their business stability.

2.5. Turnkey Services vs. Standalone Manufacturing

Determine how much of the process you want to manage yourself.

Full-Service (Turnkey): Many manufacturers offer end-to-end services, including:

Packaging Design and Sourcing: Bottles, jars, labels, etc.

Labeling and Regulatory Review: Ensuring your label is compliant with FDA/FTC regulations—a complex and crucial service.

Warehousing and Fulfillment: Storing your finished products and shipping them to your customers or distributors.

Standalone Manufacturing: You may prefer to handle packaging, labeling, and fulfillment yourself or through other partners. Clarify what services are included in their base cost.

Phase 3: The Human and Business Relationship Element

The technical aspects are paramount, but the partnership's success also hinges on softer factors.

3.1. Communication and Customer Service

Responsiveness: How quickly do they respond to your initial inquiries? This is often a indicator of their general communication style.

Dedicated Project Manager: Will you have a single point of contact, or will you be passed between departments?

Transparency: Are they open and honest about their capabilities and limitations? Do they communicate proactively about potential delays or issues?

3.2. Company Culture and Reputation

References: Always ask for and contact current clients. Ask about their experience regarding quality, communication, and reliability.

Industry Standing: How long have they been in business? Do they participate in industry events? Are they known for a particular specialty?

Philosophical Alignment: Do their values around quality, sustainability, and ethics align with your brand's?

Phase 4: Making the Final Decision

After narrowing down your list to 2-3 top candidates, take the final steps.

1. The Formal Request for Quotation (RFQ): Provide each finalist with a detailed, identical project brief including your formula, desired packaging, and volume. Compare the resulting quotes carefully, ensuring you are comparing apples to apples.

2. Pilot Batch: Before committing to a large production run, invest in a small pilot batch. This allows you to evaluate the final product's quality, taste, texture, and packaging firsthand.

3. Contract Negotiation: The manufacturing agreement must be thorough. It should cover confidentiality, quality specifications (with explicit margins of error), liability, intellectual property ownership, and protocols for handling rejected batches.

Conclusion

Selecting a B2B supplement manufacturer is a profound investment in your brand's future. Rushing this process or selecting a partner based solely on the lowest price is a high-risk strategy that can undo years of brand-building work. By following a structured, diligent approach—focusing relentlessly on regulatory compliance, quality systems, technical expertise, and communicative transparency—you can forge a powerful partnership. The right manufacturer will do more than just produce pills and powders; they will become a trusted ally, providing the solid foundation of quality, reliability, and innovation upon which a successful and enduring supplement brand is built.